R100 Safety & Adding Carpets

9th of June 2012

Preparing the Z3 for the VN/ECE R100 safety requirement. The R100 is a comprehandsive document that covers a wide range of items to comply with when peforming an electric car conversion. Id advice to read the R100 document or similar document that applies to your country when considering a conversion. This page focusses on electrical touch / wire safety.

Safety has been very high on my agenda.All steps and decessions made in the conversion has been evaluated with safety in mind. One of the last hurdles to tackle is the trunk area. I wanted to eliminate all doubt regarding the 'Wire Test' requirement stated in the R100.

The VN/ECE R100 demands IPxxD for passenger and luggage compartments and IPxxB for the motor compartment. IP (Ingress Protection) is a standard that describes the level of protection against foreign objects to enter sensitive area's. In this case, the High voltage battery pack or any exposed element of the HV circuit. Equipment & instruments may be classed from IP00 (no protection to IP68 waterproof. The way the two digits are coded is quite straight forward.

First number describes solids, second number liquids. Here is the definition.

| 1st digit | Description | Definition |

|---|---|---|

| 0 | Non-protected | No special protection |

| 1 | Protected against solid objects greater than 50 mm | A large surface of the body such as the hand (no protection against deliberate access). Solid objects exceeding 50mm diameter |

| 2 | Solid objects exceeding 12 mm diameter | Protected against solid objects greater than 12 mm Fingers or other objects not exceeding 80 mm in length. |

| 3 | Protected against solid objects greater than 2.5 mm | Tools, wires, etc of diameter or thickness greater than 2.5 mm. Solid objects exceeding 2.5 mm diameter. |

| 4 | Protected against solid objects greater than 1.0 mm | Wires or strips of thickness greater than 1.0 mm. Solid objects exceeding 1.0 mm |

| 5 | Dust protected | Ingress of dust is not totally prevented but dust does not enter in sufficient quantity to interfere with satisfactory operation of the equipment |

| 6 | Dust-tight | No ingress of dust |

| 2nd digit | Description | Definition |

|---|---|---|

| 0 | Non-protected | No special protection |

| 1 | Protected against dripping water | Dripping water (vertically falling drops) |

| 2 | Protected against dripping water when tilted up to 15º | Vertically dripping water shall have no harmful effect when the enclosure is tilted at any angle up to 15º from its normal position |

| 3 | Protected against spraying water | Water falling as spray at an angle up to 60º from the vertical shall have no harmful effect |

| 4 | Protected against splashing water | Protected against splashing water Water splashed against the enclosure from any direction shall have no harmful effect |

| 5 | Protected against water jets | Water projected from a nozzle against the enclosure from any direction shall have no harmful effect |

| 6 | Protected against heavy seas | Water from heavy seas or water projected in powerful jets shall not enter the enclosure in harmful quantities |

| 7 | Protected against the effects of immersion | Ingress of water in a harmful quantity shall not be possible when the enclosure is immersed in water under defined conditions of pressure and time |

| 8 | Protected against submersion | The equipment is suitable for continuous submersion in water under conditions, which shall be specified by the manufacturer |

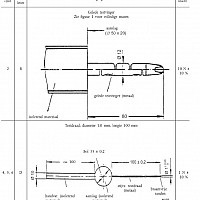

The VN/ECE R100 requires that the luggage and passenger compartments are IPxxD.. The D describes the wire test-method. A standardized 1mm thin test-wire of 100mm long will be used to verify the IPxxD ingress protection of the vehicle. Additionally the 'engine' compartment only requires IPxxB. B declares a standardized test finger of 10mm diameter and 80mm long must not be able to touch any part of the HV system. The test-finger can be formed to follow a curve like a human finger could.

The IPxxB turns out a minimum IP class of IP2x. Where IPxxD is IP4x as a minimum. Harmfull water ingress is also to be inhibited , but not while the trunk or hood is open.

This sounds simple and it is when you prepare for it.

The Battery itself is fully protected from any finger and wire access. To add an extra layer of defence, I added the carpet that completly covers the equipment. Can't poke a wire into something that is not visible and not accessable ;)

One final note. The IP classifications only apply if the protective cover can only be removed with (special tools). Screw driver, drill, knive, torch, angle grinder, Space continium transfunctioner etc etc. The carpets can be locked into place by using tye-wraps, spit-screw bolts, or plastic pin-heads with have been sealed with an adhesive. This prevents removal other than drilling it out.

This is what the trunk looks like with a carpet.

This is a copy from the R100 standard describing the test finger and wire. Click to see full page: